Researchers Develop First Fully 3D-Printed, Flexible OLED Display

In a groundbreaking new study, researchers at the University of Minnesota Twin Cities used a customized printer to fully 3D print a flexible organic light-emitting diode (OLED) display.

The discovery could result in low-cost OLED displays in the future that could be widely produced using 3D printers by anyone at home, instead of by technicians in expensive microfabrication facilities.The OLED display technology is based on the conversion of electricity into light using an organic material layer. OLEDs function as high quality digital displays, which can be made flexible and used in both large-scale devices such as television screens and monitors as well as handheld electronics such as smartphones. OLED displays have gained popularity because they are lightweight, power-efficient, thin and flexible, and offer a wide viewing angle and high contrast ratio.

The researchers wanted to see if we could basically condense all of that down and print an OLED display on our table-top 3D printer, which was custom built and costs about the same as a Tesla Model S.

The group had previously tried 3D printing OLED displays, but they struggled with the uniformity of the light-emitting layers. Other groups partially printed displays but also relied on spin-coating or thermal evaporation to deposit certain components and create functional devices.

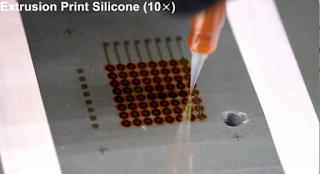

In this new study, the University of Minnesota research team combined two different modes of printing to print the six device layers that resulted in a fully 3D-printed, flexible organic light-emitting diode display. The electrodes, interconnects, insulation, and encapsulation were all extrusion printed, while the active layers were spray printed using the same 3D printer at room temperature. The display prototype was about 1.5 inches on each side and had 64 pixels. Every pixel worked and displayed light.

The discovery could result in low-cost OLED displays in the future that could be widely produced using 3D printers by anyone at home, instead of by technicians in expensive microfabrication facilities.The OLED display technology is based on the conversion of electricity into light using an organic material layer. OLEDs function as high quality digital displays, which can be made flexible and used in both large-scale devices such as television screens and monitors as well as handheld electronics such as smartphones. OLED displays have gained popularity because they are lightweight, power-efficient, thin and flexible, and offer a wide viewing angle and high contrast ratio.

The researchers wanted to see if we could basically condense all of that down and print an OLED display on our table-top 3D printer, which was custom built and costs about the same as a Tesla Model S.

The group had previously tried 3D printing OLED displays, but they struggled with the uniformity of the light-emitting layers. Other groups partially printed displays but also relied on spin-coating or thermal evaporation to deposit certain components and create functional devices.

In this new study, the University of Minnesota research team combined two different modes of printing to print the six device layers that resulted in a fully 3D-printed, flexible organic light-emitting diode display. The electrodes, interconnects, insulation, and encapsulation were all extrusion printed, while the active layers were spray printed using the same 3D printer at room temperature. The display prototype was about 1.5 inches on each side and had 64 pixels. Every pixel worked and displayed light.

No comments: